P model

The pod is today a response to the requests of consumers who want a functional, ecological, economic, practical product. All the pod filling machines are equipped with a bagging machine to pack the pod in a single bag, or in a bag both with an inert atmosphere to preserve taste and aroma. Over the years, Gr Pack has developed many pod formats, so the machines are designed with the aim of having an extremely rapid and inexpensive format change. The Gr Pack pods filling machines are compact, reliable machines capable of transforming the roasted coffee bean into a ready-to-use pod.

AVAILABLE OPTIONS

- Ready for Industry 4.0.

- Possibility of table systems for semi-automatic filling of boxes / cases.

- Possibility of connection to a bagging machine to make square bottom bags with 4 edges.

- Kit for tea, herbal tea, barley, soluble and liquid.

- Format change (available for 60/100).

OPERATING CYCLE

- Suction of coffee beans and instant grinding.

- Unrolling of filter paper reels with preparation of the pod shape, possibility of working with compostable materials.

- Dosing and pressing of the coffee with disk system to guarantee weight consistency, possibility of installing weight control with feedback.

- Forming the coffee pod with adjustable pressure.

- Possibility to add the liquid dispenser for flavorings.

- Hot welding station.

- Paper cutting station with customizable shapes and dimensions.

- Integrated bagging machine for single packaging complete with stamping machine for date / lot and nitrogen injection system for packaging in modified atmosphere.

- Tape for counting pods when filling boxes.

- Machine control through a multilingual touch-screen control panel.

FV 50D

Speed:

Production up to 50 Drip coffee pods/minute

Dimensions:

Size varies depending on the format installed

Power:

4 kW

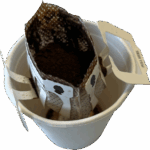

Filter paper bag forming machine for drip coffee in various sizes and dosages. Drip coffee is a special pod that can be opened at the top and is designed to be attached to a glass or mug. At this point, simply pour boiling water over it and the percolation process will produce an excellent long coffee.

Pneumatic consumption 300Nl/min

Nitrogen consumption 40 Nl/min

SYSTEM DESCRIPTION:

The machine is equipped with an upper grinder that grinds the coffee and sends it to a special dosing screw with an agitator that ensures fast and constant filling of the pod, formed from a special coil by means of folds and welds. The supply is completed by an bagging machine that inserts the pod into a barrier bag with inert gas, also formed from a coil.

The machine is very flexible and can also produce large pods suitable, for example, for making American-style coffee. In these cases, the machine can be equipped with a valve applicator for inserting a degassing valve.

AVAILABLE ACCESSORIES:

Grinder

Rotary table

Thermal transfer printer

Valve applicator

Bag counting belt

GR 60P

Speed:

Production up to 60 pods/minute

Dimensions:

2000 x 1400 x 2600 mm (LxWxH)

Power:

6 kW

Compact multi-format pod making machine capable of forming filter paper pods and enveloping them in a single bag in a modified atmosphere up to a speed of 60 pods / minute.

The pods are made with two layers of heat-sealing filter paper, which may be compostable, with larger rolls positioned on the front of the machine.

The machine is designed for a quick format change with dozens of different types of pods available.

The Gr60P pod making machine can pack coffee, tea, leaf products, barley.

The Gr60P pod making machine is pneumatically operated, with coffee dosing and pressing with a disc system to guarantee weight consistency, and the possibility of installing weight control with feedback.

- Pneumatic consumption 1100 Nl / min

- Nitrogen consumption 20 Nl / min

AVAILABLE OPTIONS:

- Aspirator for ground coffee / tea / barley

- Grinder for coffee beans

- Doser kit for tea / barley

- Aromatizer

- Weight control with feedback

- Vision system

- Bagging machine

- Semiautomatic filling table for boxes / cases

GR 100P

Speed:

Production up to 100 pods/minute

Dimensions:

3000 x 1300 x 2600 mm (LxWxH)

Power:

10 kW

Compact multi-format pod making machine capable of forming filter paper pods and enveloping them in a single bag in a modified atmosphere up to a speed of 100 pods / minute.

The pods are made with two layers of heat-sealing filter paper, which may be compostable, with larger rolls positioned on the front of the machine.

The machine is designed for a quick format change with dozens of different types of pods available.

The Gr100P pod making machine can pack coffee, tea, leaf products, barley.

The Gr100P pod making machine machine has a mechanical cam operation, with dosing and pressing of the coffee with a disc system to guarantee weight consistency, and the possibility of installing weight control with feedback.

- Pneumatic consumption 1000 Nl / min

- Nitrogen consumption 30 Nl / min

AVAILABLE OPTIONS:

- Aspirator for ground coffee / tea / barley

- Grinder for coffee beans

- Doser kit for tea / barley

- Aromatizer

- Weight control with feedback

- Vision system

- Bagging machine

- Semiautomatic filling table for boxes / cases

GR 200P

Speed:

Production up to 200 pods/minute

Dimensions:

2500 x 1500 x 2600 mm (LxWxH)

Power:

18 kW

Linear system with two tracks that produces pods in filter paper. Pods can be in hard or soft format and in different sizes.

The machine has also a pouches station for single bags, filled with inert gas.

PLANT DESCRIPTION:

- Unwinding station for bottom filter paper, equipped with dual 65 mm band reels with pneumatically operated reel holder and oversized reels for maximum autonomy.

- Pre-cutting station for bottom and cap filter paper, pneumatically operated and with mechanical position adjustment to allow optimal wafer forming.

- Mechanical drive of the machine with a single motor, cam belts and intermittents for a mechanical timing of the machine that minimises the need for adjustments.

- Double volumetric disk-type ground coffee dosing station with pneumatic piston (and independent weight adjustment), mechanical movement with belt drive and ground toothed wheels to ensure maximum precision in weight and cleanliness of the outer rim and wafer height.

- POD moulding station with mechanical compaction with cam always with adaptable pod hardness to ensure maximum precision in weight, external cleaning and pod moulding; Brushless press rotation.

- Unwinding station for top filter paper, equipped with double 65 mm strip reel with pneumatically operated reel holder and oversized reels for maximum autonomy.

- Dual top/bottom filter paper sealing station with temperature control of the sealing element and cycle time, with micrometric adjustment of the sealing position.

- Double die-cutting/filter paper cutting station (with tab or flap obtainment).

- POD conveyor to the packaging machine, with the possibility of installing automatic visual control for pod inspection and rejection of unsuitable pods (optional)

- Double vertical pod wrapping station in single pouch (one pod per pouch) with inert gas (nitrogen) insufflation and sealing on 3/4 sides using triple laminated film; vacuum belt drive system to ensure perfect pouches with all types of film; automatic edge guiding system to keep reel edges aligned and ensure perfect pouches at all times.

- Modem for remote assistance.

AVAILABLE OPTIONS:

- Grinder

- Rotating table

- Thermal transfer printer